U-ME SYSTEM FEATURES

Now your prints will be repetitive regardless of the selected material! Thanks to our algorithm, P800D achieve dimensional stability of the printed elements and a tolerance of 0.05 mm in each axis of the printed detail.

Your printer will inform you that filament is running out!

Material delivery control:

The 3D printer is able to detect not only the end of the filament on the roll, but also possible problems with its delivering to the extruder (e.g. clogged nozzle, entangled material, etc.).

Material weight measurement:

The 3D printer software checks the progress of work e.g. via mobile devices. User can check the actual data of the amount of remaining material at any time and replace it before it is finished. Additionally, the 3D printer informs about critical states with messages sent by the application. For example, 1 hour before the end of the material on the roll, the user receives a notification about the impending need to replace the filament. Other types of notifications include stopping printing due to a problem and information about finished printing.

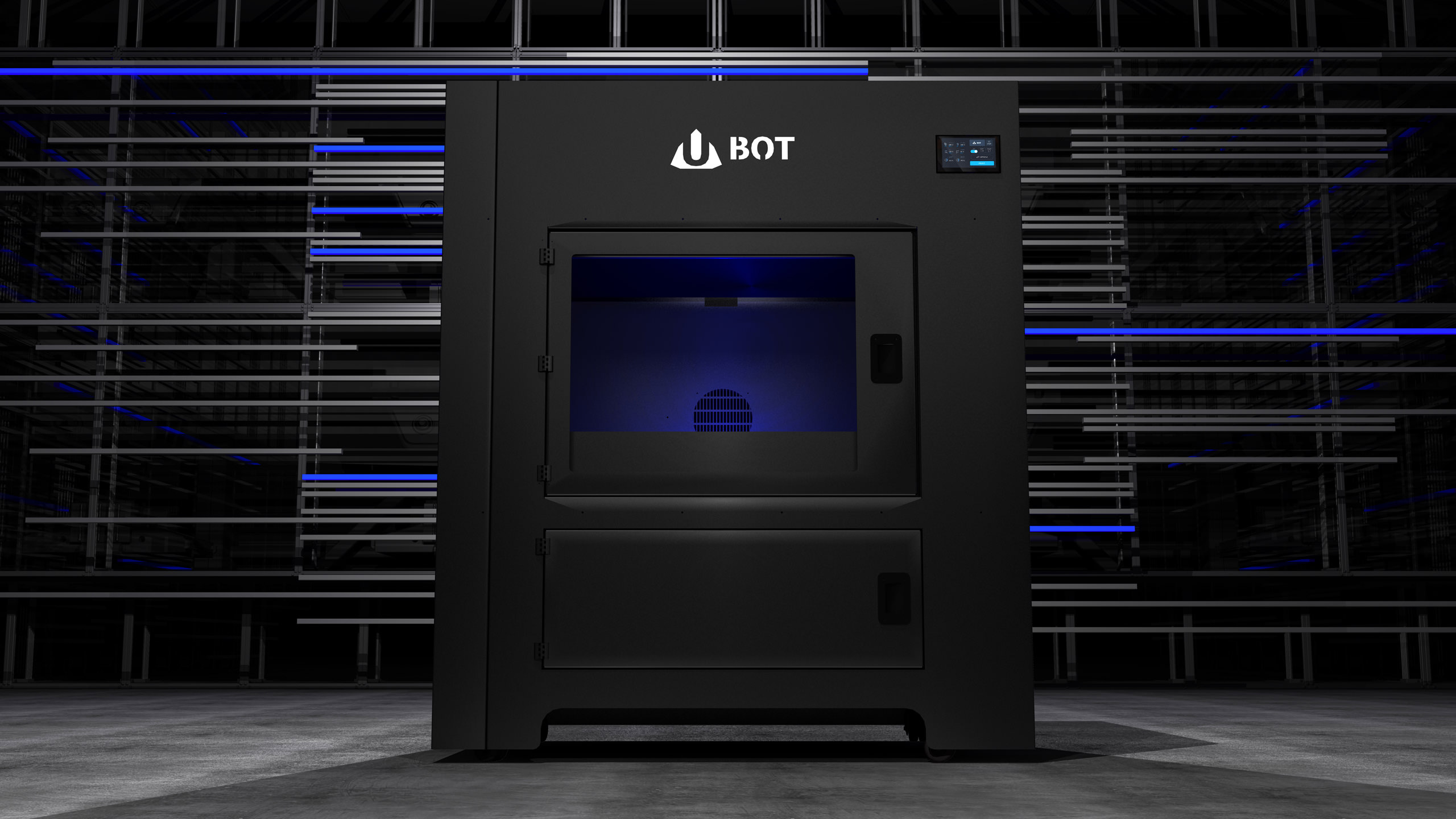

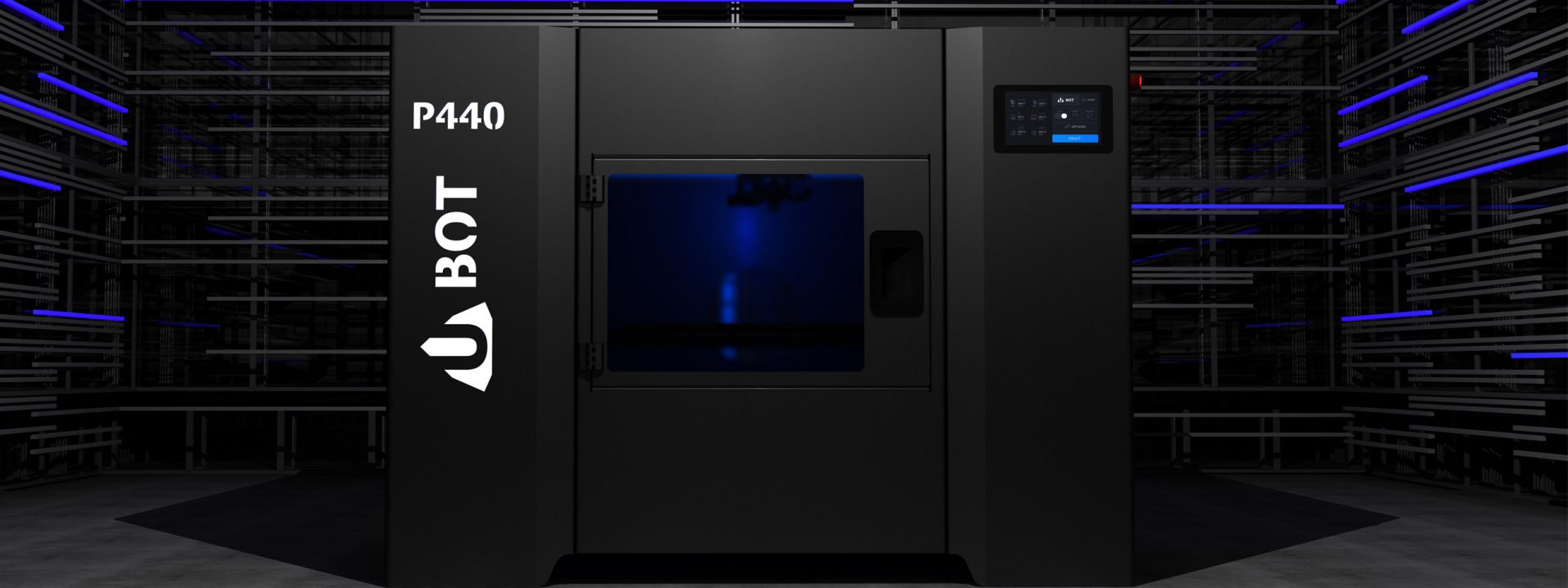

LARGE-FORMAT INDUSTRIAL 3D PRINTINGS

The impressive working area of 800 mm x 500 mm x 500 mm allows you to print large-format models during one printing process, without spliting them into parts. Thanks to that, final model has greater durability, provide time savings, and guarantees continuity of processes and satisfaction of use.

ADDITIONAL ENERGY, ALWAYS WHEN NEEDED

The P800D printer is equipped with the proprietary countercurrent protection and energy support system. When system detects lack of energy, the device is able to work for 15 minutes maintaining the previously set printing parameters. Thanks to that, we can be sure that the print will be finished!

BUILT-IN MEMORY, CAMERA AND WI-FI CONNECTIVITY!

You can copy your files directly to the printer’s memory, or download remotely via Wi-Fi and view the printing process in HD quality from anywhere in the world through a dedicated mobile application.

CLOSED AND HEATED WORKING CHAMBER

The 3D printer is equipped with a heated working chamber by an independent heating system with a power of 2500W. In the P800D, heat is distributed using several independent fans – the air movement does not cause any sudden changes of temperature. Temperature in chamber can be fully controlled through printer software during printing process. The air is removed from the chamber by another fan and filtered by the four layer filter: HEPA, carbon, PP and cold catalysis. Thanks to this solution, we can achieve more stable printing process and the ability to print details from materials with increased shrinkage such as ABS, PC-ABS, POLYAMIDE ASA, HIPS, NANO-CARBON on the entire working field!

USE DIFFERENT MATERIALS DEPENDING ON YOUR NEEDS!

The P800D printer is equipped with a HOTEND HELLFIRE which allows printing from high-temperature materials. In connection with our UBOT HERKULES extruder, which extrude material with double force (double jugger), it allows the use of a huge range of filaments, including PEEK, the most desirable for 3D printing in the aerospace industry, a material with high stiffness, strength and temperature resistance.

Technical Specification

| Printing technology: | FFF (Fused Filament Fabrication) |

|---|---|

| Print area (x,y,z): | 800 x 500 x 500 mm |

| Layer resolution: | from 20 microns |

| Extruder: | 2 printing heads |

| Nozzle diameter: | 0.2/1.2 mm, also special strengthened nozzles |

| Minimal wall thickness: | 0.2/1.2 mm |

| Filament diameter: | 1.75 mm |

| Filament flow detection: | Yes, 2 independent systems |

| Certified materials: | PLA, ABS, HIPS, PET, Nylon, PP, ASA,PC, NanoCarbon, TPU, B-FLEX, PC-ABS, ESD, PEEK, Ultem, PPSU, others |

| Support materials: | Additional extruder for support materials: HIPS, BVOH, PVA |

| Chamber filter: | YES; 4 layer, PP, HEPA, cold catalysis, active carbon |

| Printing temperature (extruder): | up to 400°C |

| Platform temperature: | up to 160°C |

| Chamber temperature: | up to 80°C |

| Positioning precision XY: | 2.4 microns |

| Positioning precision Z: | 0.8 microns |

| Working platform: | aluminum magnetic platform with an adhesive pad and light |

| Auto calibration: | YES |

| Connections: | USB, WIFI, built-in memory |

| Remote printing: | YES; smartphone , PC application |

| Additional features: | U-ME system, preview from HD camera, power support system, full range of temperature control during printing, real-time parameter change – temperature, speed, cooling; material end sensor with material weight control |

| Dimensions: | 1110 x 605 x 730 mm |

| Printer weight: | 680 kg |

| Power: | 240V AC ~ 36A 50/60 Hz |

| Power consumption: | max 6000 W |

| Software: | Simplify3D with material profiles |

| Supported files: | .stl, .obj |

| Safety certifications: | CE |

| Warranty: | 2 years |